Safely tested. Documented in accordance with standards. Fully integrated.

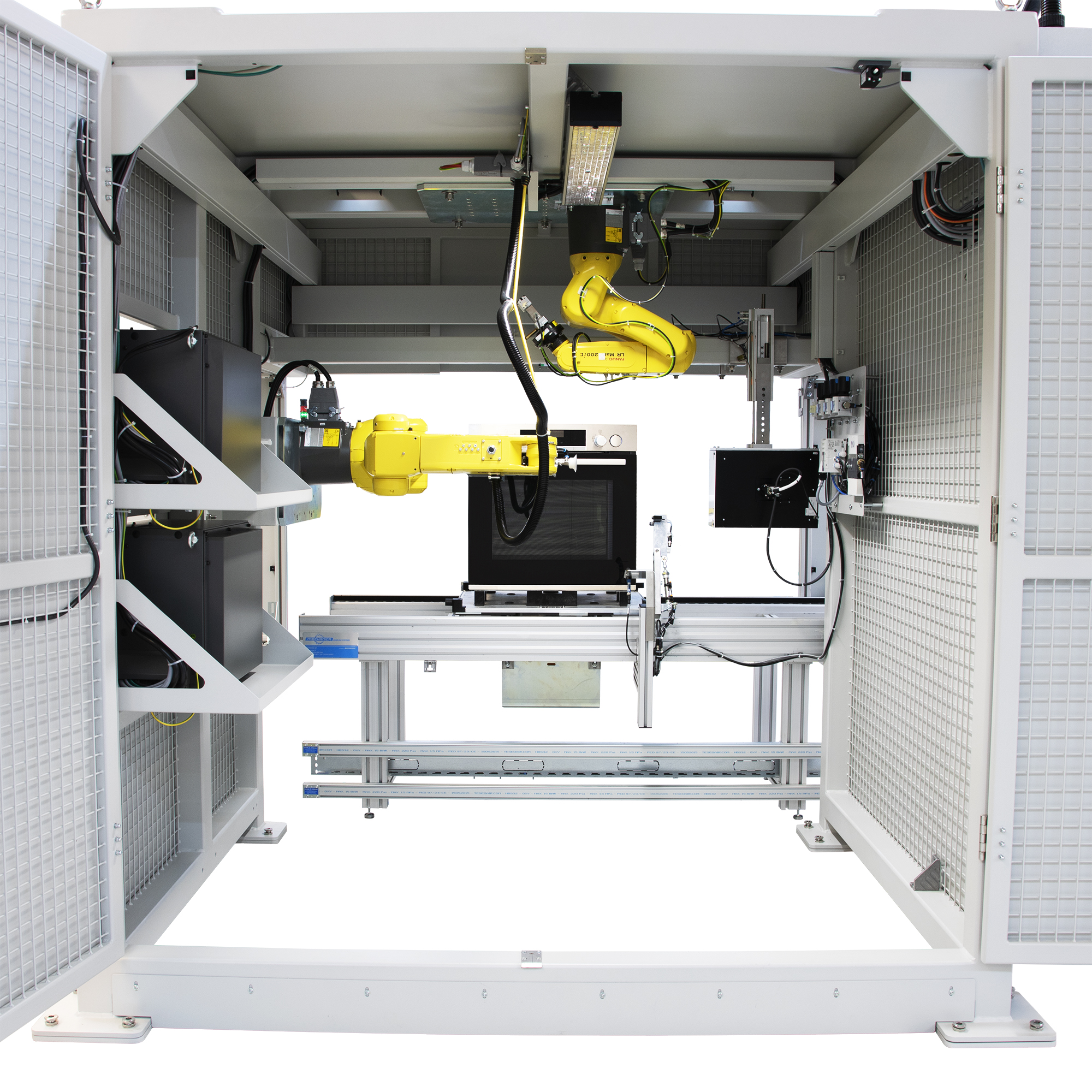

Electrical Safety Testing as Integrated Test System Solutions

Safety and Compliance for Every Industry – Manual, Semi-, or Fully Automated

Electrical Safety as a Core Element of Quality Assurance

Across both development and high-volume production, electrical safety testing is an essential part of product validation. Whether it's a medical device, charging infrastructure, or household appliance, compliance with mandatory safety standards such as DIN EN, VDE, IEC, or UL is critical.

Bott offers comprehensive solutions to enhance the efficiency and precision of electrical safety testing – providing full documentation for a range of processes from manual workstations to fully automated systems.