bott workstation solutions create ideal conditions for efficient maintenance and standard-compliant servicing: modularly configurable, ergonomically equipped and digitally integrable.

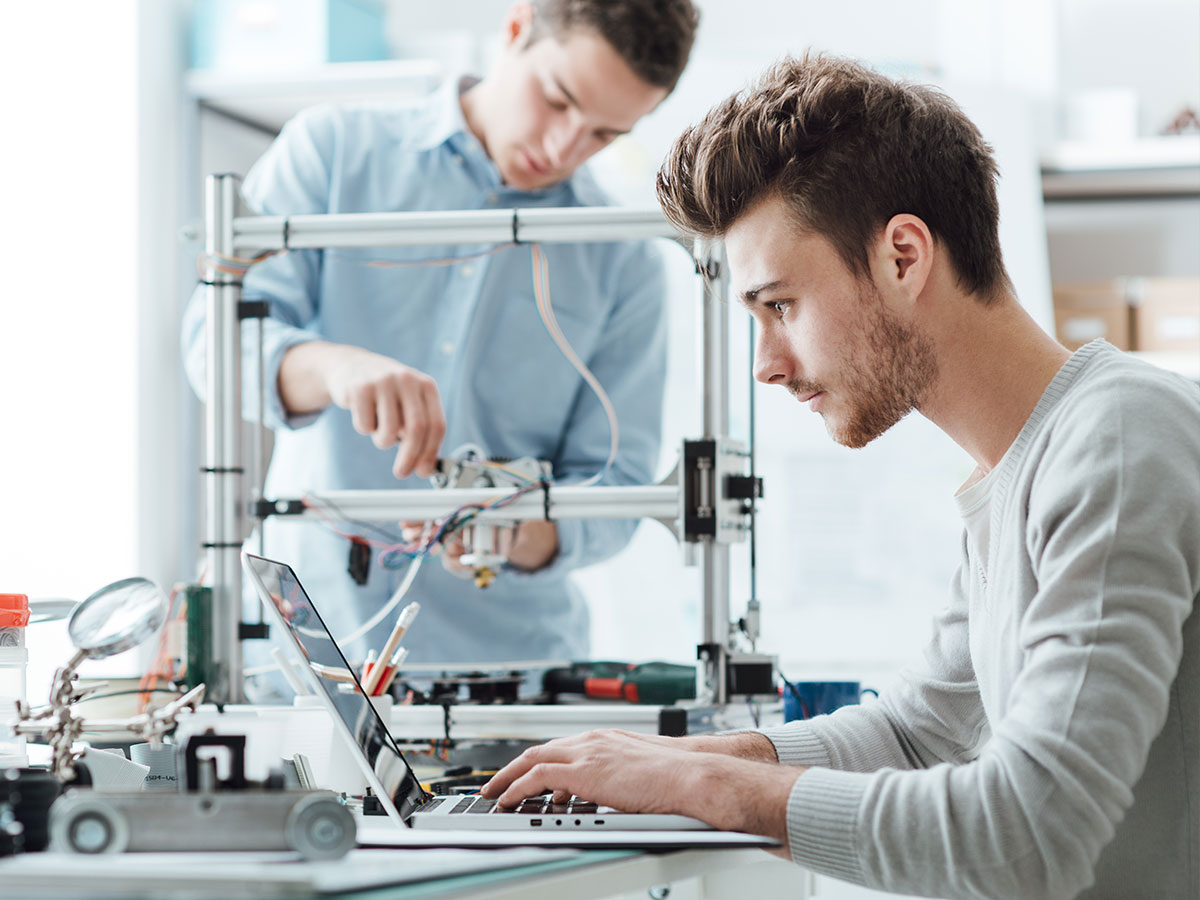

Smart workstation systems for maintenance & servicing

Maintenance and servicing are essential across many settings — from series production to service centers to technical operations. To ensure operational safety, uptime, and long equipment life, Bott’s professional workstation systems offer the perfect platform: ergonomically designed, modular in setup, and digitally connected for the needs of modern industry.

Why workstation systems are ideal for maintenance tasks

Maintenance work often involves changing conditions, a wide variety of components, and evolving requirements. A professional workstation system provides the flexibility and functionality to meet these demands:

- Modularity: Configurable for any maintenance task, with easily interchangeable media, tools, and fixtures.

- Ergonomics: Height-adjustable tables, optimized lighting, and tool-centric layouts enhance efficiency and reduce physical strain.

- Safety: ESD protection, certified power supply, and structured cable/air line routing safeguard both technicians and sensitive equipment.

- Digital Integration: Enables automatic capture and transfer of test and diagnostic data to ERP, maintenance, or CAQ systems.

- Mobility & Scalability: Available as mobile, fixed, or networked solutions, from compact service units to fully equipped workshops.