Flexible. Modular. Fully networked.

Making your assembly fit for tomorrow.

Industrial assembly

From manual to fully automated: flexible. modular. future-proof.

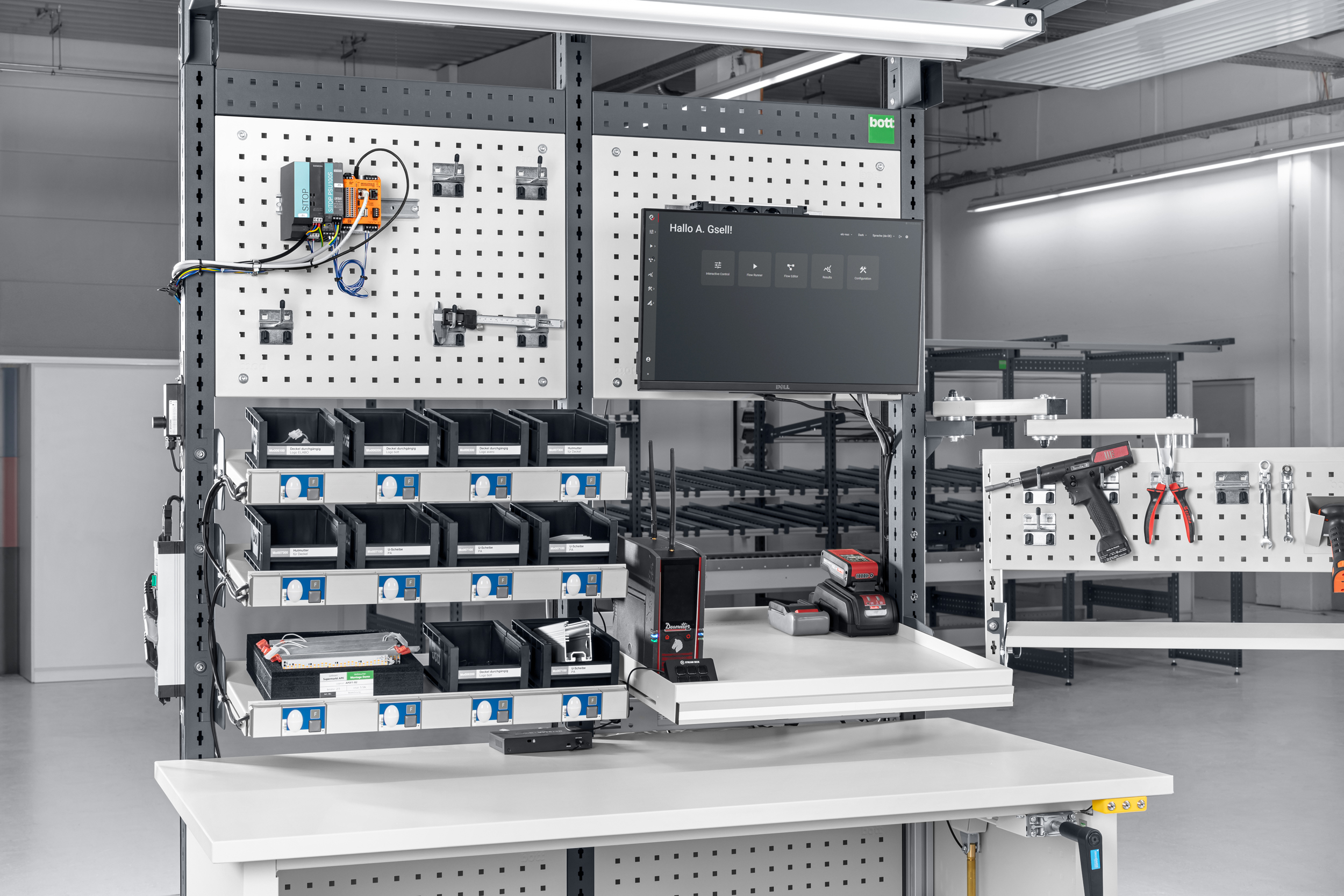

Industrial assembly demands both high efficiency and maximum variability. Whether manual assembly, semi-automated processes, or fully automated assembly lines – modern workstation systems must flexibly adapt to individual manufacturing workflows. With avero, elution, intelligent testing systems, and digital inspection modules, bott offers solutions that scale with your requirements.