When everything has to be right in the end: Functional tests - safe, flexible, documented.

Functional testing in industry

Custom test systems for your quality control

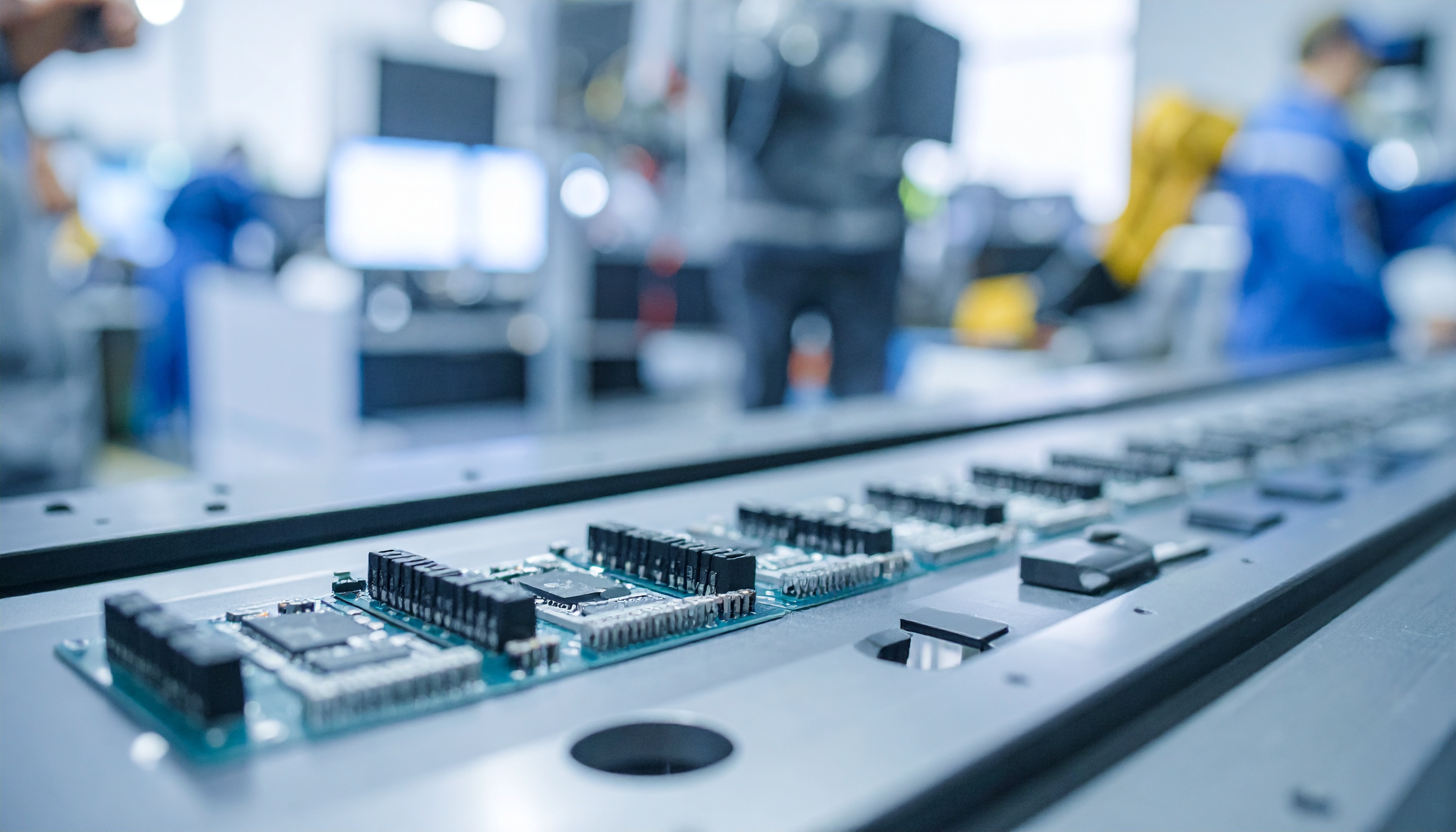

The end of every production line – where functionality matters most

Whether it's an automotive part, a medical device, or a household product, functional testing is the decisive final step before a product is shipped. Quality assurance at this phase is critical to ensuring a product is complete, safe, and ready for use.

Bott provides flexible, modular functional test systems tailored precisely to your testing scenarios and product requirements, whether manual, semi-automated, or fully automated.